VaPOR RECOVERY TOWERS

Vapor Recovery Towers (VRTs)

Fossil Manufacturing offers standard VRTs and our patented Max VRT. Vapor Recovery Towers (VRTs) are used to prevent oxygen in the flash gas stream.

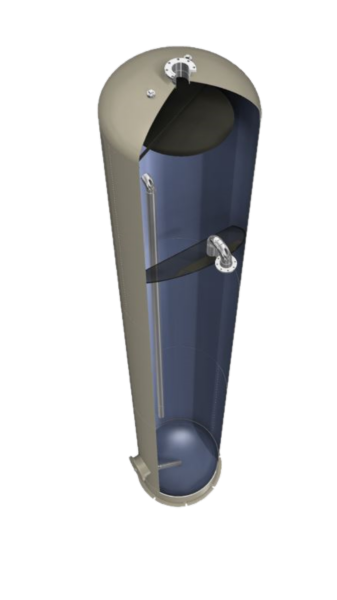

Standard VRT

Features

-

Painted Pallet Tan (other colors available on request).

-

Non-Code (coded vessels available upon request).

-

Riffle board placed below oil inlet for increased break-up and flash potential.

-

3-point guy wire tie-offs placed on multi-positionable clamp for easy rig-up.

-

Gas outlet line to VRU re-positionable up to 360 degrees for easy rig-up.

-

Auxiliary oil outlet provided to lower liquid level and prevent flooding during initial well start-up spikes and excessive flow conditions.

-

2″ relief valve assembly provided loose.

Options

-

Heavy duty concrete base.

-

Guy wire kit with clamps and cable eyelets.

-

Sight glass kit with mesh protector.

(above items can be provided as an accessory kit) -

Delivery and set-off at location on 60″ towers and below (includes dunnage boards, does not include tower set-up).

To download full standard VRT brochure, click here.

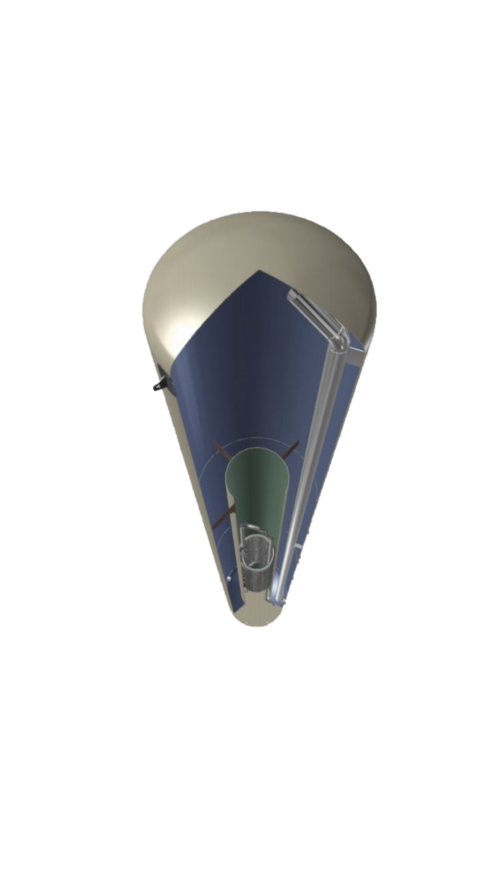

Fossil Max VRT

How it works

- Increases product temperature by introducing (free) heat from the VRU compressor discharge, or other available sources, both gas and liquid.

- Reversal of product flow allows hydrostatic pressure to decrease during retention time instead of increase.

- Lighter constituent flash-off aerates and agitates the increasingly lighter liquid column as product rises in the tower. The best chance for flash-off of heavier constituents is inside the tower, not in your tanks.

Benefits over Standard Towers

- Increase of revenue from high BTU flash gas sales.

- Reduces RVP concerns with downstream purchasers.

- Easy rig-up due to multiple clocking positions on connections.

- Cost is competitive with Standard VRT’s, higher potential for ROI.

- Reduces the size, or negates the need for further downstream control devices.

- Alleviates requirement for a VRU aftercooler when discharge gas is used for heating.

- Design significantly reduces the chance of flooding the tower during production spikes.

- Installed riffle trays extend product retention time within the low pressure gas cap area.

For the MAX VRT brochure, click here.