ComBUSTION GAS BOOSTER

combustion Gas booster

Problem

Tank Vent-Line System pressure drops result in venting at the tanks instead of flash gas flowing to the

combustor.

Solution

The Fossil Combustion Gas Booster system, keeps gas emissions at the tanks under control by boosting vent-line gas pressure to the Combustor and maintaining a tank gas cap pressure setpoint as determined by the operator.

Features

- The PLC/VFD based control system adjust booster speed and monitors operation to maintain pressure at the preferred set point.

- System alarms on a low set point indicating flow

restriction upstream of booster such as, plugged off flame arrestor etc. - Maximum operating speed can be adjusted to prevent over-running combustor due to gas flow spikes.

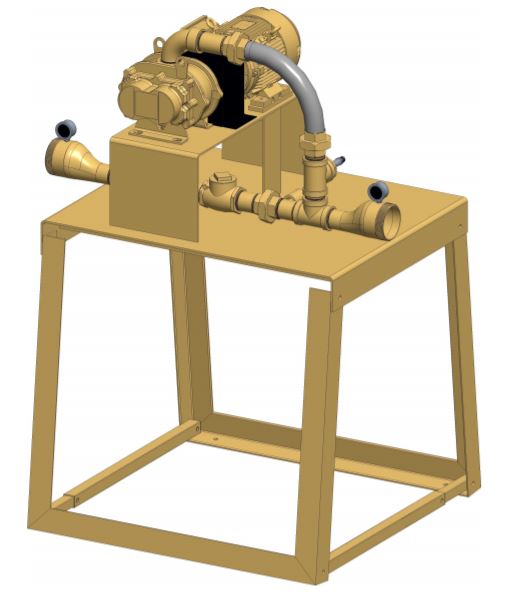

- Simple skid base design with field adjustable height, installs in-line on most piping systems, with no p-traps.

- Flow-through manifold allows liquid pass through

during operation or when booster is idle. - 480-3 phase or 240 single-phase power options

available. - H2S and wet gas compatible package design.

Capacity

- Size 1: 2HP, 10-50 MSCFD

- Size 2: 3HP, 20-100 MSCFD

- Size 3: 5HP, 40-200 MSCFD

(other flow ranges are available upon request)

Click here to download a brochure.